STANDARDISED INDUSTRIAL GEARBOXES

Gearboxes for double-screw extruders

Conical planetary gearboxes structurally adjusted for high and uneven dynamic loads offer an innovative solution for twin-screw extruder drives.

Planetary gearboxes significantly decrease drive weight and dimensions, saving raw material and power throughout the entire gearbox’s lifetime – production, transport, storage, installation, operation and disposal, guaranteeing a positive impact on the environment and costs.

The unique gearbox structure allows in certain cases for the driven cylinder to be directly anchored for easier installation, especially to meet requirements for coaxial shaft alignment.

There is a hollow output gearbox shaft for cooling medium transfer.

Drives can be delivered with the following accessories: electric motor, cooling system, anchor elements, sensors and units for diagnostics and evaluation.

Technical specifications:

| Constant torque | up to 50kNm |

| Output speed | up to 27 1/min |

Technical specifications can be modified to meet customer specific requirements.

Sectors:

Rubber industry

References:

Continental Púchov

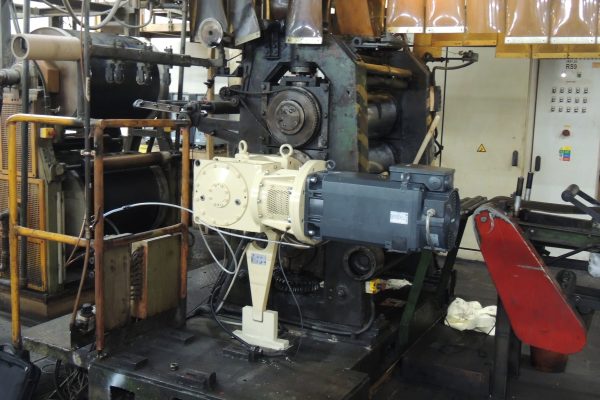

Gearboxes for rubber polishers and roller mills

An innovative solution for double- and multiple-roller rubber machine drives is conical planetary gearboxes structurally adjusted for high and uneven dynamic loads.

Planetary gearboxes significantly decrease drive weight and dimensions, saving raw material and power throughout the entire gearbox’s lifetime – production, transport, storage, installation, operation and disposal, guaranteeing a positive impact on the environment and costs.

The unique gearbox structure allows in certain cases for the driven cylinder to be directly anchored for easier installation, especially to meet requirements for coaxial shaft alignment, while cardan shafts are not required.

A common reaction frame records the reaction moments of a pair of gearboxes to enable mutual shift and crossing of rollers (cross bending). This solution is patented.

Also standard in the drive delivery is an embedded multi-plate brake with pneumatic release, which in an emergency stops the rotating rollers at the required turning angle.

Drives can be delivered with the following accessories: cooling system, electric motor, anchor elements, sensors and units for diagnostics and evaluation.

Technical specifications:

| Output speed | 1.5 – 40 1/min |

| Torque | 1.5 – 200 kNm |

Technical specifications can be modified to meet customer specific requirements.

Sectors:

Rubber industry

Priemysel:

Gumárenský priemysel

Gearboxes for belt conveyors

An innovative solution for belt conveyors drives is conical planetary gearboxes structurally adjusted to work under specific operating conditions such as high loads, extreme temperatures, dust, humidity, frequent start-ups, and reverse runs.

Planetary gearboxes significantly decrease drive weight and dimensions, saving raw material and power throughout the entire gearbox’s lifetime – production, transport, storage, installation, operation and disposal, guaranteeing a positive impact on the environment and costs.

The unique gearbox structure allows in certain cases for the driven cylinder to be directly anchored for easier installation, especially to meet requirements for coaxial shaft alignment.

Drives can be delivered with the following accessories: electric motor, brake against reverse movement, start-up clutch, cooling system, heater, anchor elements, sensors and units for diagnostics and evaluation.

Technical specifications:

| Parameter | Value |

| Output | up to 1500kW |

| Torque | up to 300 kNm |

| Gear ratio | 16 – 200 |

Technical specifications can be modified to meet customer specific requirements.

Sectors:

Metallurgy

Mining industry: extraction and processing of minerals

Energy industry: power generation, heating plants and thermal power plants

Paper and wood pulp production

Cement industry

Sugar refineries

Gearboxes for chain conveyors

An innovative solution for chain conveyors drives is planetary and conical planetary gearboxes structurally adjusted to work under specific operating conditions such as high loads, extreme temperatures, dust, humidity, frequent start-ups, and reverse runs.

Planetary gearboxes significantly decrease drive weight and dimensions, saving raw material and power throughout the entire gearbox’s lifetime – production, transport, storage, installation, operation and disposal, guaranteeing a positive impact on the environment and costs.

The unique gearbox structure allows in certain cases for the driven cylinder to be directly anchored for easier installation, especially to meet requirements for coaxial shaft alignment.

Another unique solution is the intelligent mechanical overload lock embedded directly in the gearbox to protect against corrosion, dust and mechanical damage. Cut-off torque can be continuously changed to reflect current operational requirements.

Drives can be delivered with the following accessories: electric motor, overload lock, start-up clutch, cooling system, anchor elements, sensors and units for diagnostics and evaluation.

Technical specifications:

| Parameter | Value |

| Torque | up to 630 kNm |

| Gear ratio | up to 3150 |

*Technical specifications can be modified to meet customer specific requirements

Sectors:

Metallurgy

Mining industry: extraction and processing of minerals

Energy industry: power generation, heating plants and thermal power plants

Gearboxes for sintering and cooling belts

An innovative solution for sintering and cooling belts is planetary or planetary front gearboxes to work under specific operating conditions such as high loads, extreme temperatures, dust, humidity, frequent start-ups, and reverse runs.

Planetary gearboxes significantly decrease drive weight and dimensions, saving raw material and power throughout the entire gearbox’s lifetime – production, transport, storage, installation, operation and disposal, guaranteeing a positive impact on the environment and costs.

The unique gearbox structure allows in certain cases for the driven cylinder to be directly anchored for easier installation, especially to meet requirements for coaxial shaft alignment.

Another unique solution is the intelligent mechanical overload lock embedded directly in the gearbox to protect against corrosion, dust and mechanical damage. Cut-off torque can be continuously changed to reflect current operational requirements.

Drives can be delivered with the following accessories: reverse run brake, overload lock, start-up clutch, cooling system, electrical motor, anchor elements, sensors and units for diagnostics and evaluation.

Technical specifications:

| Torque | up to 1,000 kNm |

| Gear ratio | up to 6,000 |

*Technical specifications can be modified to meet customer specific requirements

Sectors:

Metallurgy

Gearboxes for screw pumps and turbines

An innovative solution for screw pumps and screw turbines drives is planetary and conical planetary gearboxes.

Planetary gearboxes significantly decrease drive weight and dimensions, saving raw material and power throughout the entire gearbox’s lifetime – production, transport, storage, installation, operation and disposal, guaranteeing a positive impact on the environment and costs.

The unique gearbox structure allows in certain cases for the driven cylinder to be directly anchored for easier installation, especially to meet requirements for coaxial alignment of shafts and the entire assembly.

Drives can be delivered with the following accessories: electric motor, break against reverse movement, cooling system, anchor elements, sensors and units for diagnostics and evaluation.

Technical specifications:

| Output | up to 132 kW |

| Torque | 30 – 120 kNm |

Technical specifications can be modified to meet customer specific requirements.

Sectors:

Water management

Wastewater treatment plants

Pumping stations

Small hydro power plants

Gearboxes for bridge travel drives

Our portfolio offers customers two bridge travel drive solutions:

ELECTRICAL WHEEL – the gearbox in the travel wheel itself; or

PK – the aggregate is composed of planetary gearbox with electric motor and connected to a separate travel wheel.

ELECTRICAL WHEEL – the entire aggregate consists of an electric motor connected by a flange to a high gear-ratio planetary gearbox, where the gearbox is the travel wheel itself. A high-quality all-rubber or steel banding is mounted on the gearbox.

EK 517 electrical wheels are suitable for bridge travel drives in settling and secondary settling tanks.

EK 351 electrical wheels are suitable mostly for bridge travel drives in both sand and grease traps and in settling and secondary settling tanks. They work in tandem on a single travel bridge. A connection plate or flange attaches the aggregate to the bridge. It is often used to repair existing bridge travels as it can be an easy and quick substitute for the original drives, requiring minimum adjustments to the bridge frame.

| EK 517 Electrical Wheel | |||

| Oil capacity | approx. 1L | ||

| Weight | approx. 120 kg | ||

| Travel wheel diameter (all-rubber bandage) | Ø 456 mm | ||

| Travel wheel diameter (steel bandage) | Ø 310 mm | ||

| Permissible wheel load (all-rubber or steel bandage) | 37 – 50 kN | ||

| Travel speed | 1.9 m.min-1 | 2.5 m.min-1 | 3.93 m.min-1 |

| Electric motor output power | max 0.55 kW | max 0.75 kW | max 1.1 kW |

| Constant output torque | 3.1 kNm | 2.9 kNm | 2.9 kNm |

| Constant effective tension | 13.5 kN | 12.7 kN | 12.7 kN |

| EK 351 Electrical Wheel | |||

| Oil capacity | approx. 1L | ||

| Weight | approx. 135 kg | ||

| Travel wheel diameter | Ø 310 mm | ||

| Permissible wheel load | 50 kN | ||

| Travel speed | 1.9 m.min-1 | 2.5 m.min-1 | 3.9 m.min-1 |

| Electric motor output power | max 0.55 kW | max 0.75 kW | max 1.1 kW |

| Constant output torque | 2.2 kNm | ||

| Constant tensile force | 2 x 14 kN | ||

Advantages:

Compact

Low weight

Small oil capacity

Option of using organic oils

Easy to install and maintain

Long life

High-quality all-rubber bandings easy to replace

PK gearbox aggregates are suitable for bridge travel drives in circular settling and secondary settling tanks. Depending on the tank’s diameter and installation site, the drives use either single or double aggregate, or a combination of a PK gearbox aggregate with a VK tug wheel. PK aggregates are used mostly to repair existing bridge travels, enabling easy and quick replacement of the original drive.

The entire aggregate consists of an electric motor connected by a flange to a high gear-ratio planetary gearbox. The hollow output gearbox shaft glides directly onto the travel wheel shaft.

| Type identification | PK 531 | PK 707 | PK 826 |

| Gear ratio | 531 | 707 | 826 |

| Electric motor output power | 0.37 – 0.55 kW | 0.75 – 1.5 kW | 2.2 kW |

| Output gearbox speed | 1.23 ; 1.70 ; 2.62 min -1 | 1.26 and 2 min-1 | 1.1 min-1 |

| Constant output torque | 1.5 – 3 kNm | 4.1 – 5.3 kNm | 12 kNm |

| Oil capacity | 2L | 2.1L | 6L |

| Weight | 125 kg | 160 kg | 410 kg |

Installation sites

Wastewater treatment plants

General use

The aggregate structure and parameters can be adjusted to meet a specific requirement.

ADVANTAGES

Compact

Low weight

Small oil capacity

Option of using organic oils

Easy to install and maintain

Long life

ACCESSORIES – tow and tug travel wheel, incl. bearing.

CUSTOM-MADE INDUSTRIAL GEARBOXES